Rebar is really a fundamental metal bar or block that is broadly utilized in bolstered concrete and bolstered masonry structures. These rebars normally are made out of carbon metal and should be recounted as reinforcing steel or just just reinforcement. Under Structural BIM Solutions Rebar detailing is often a discipline of creating fabrication or shop drawings of metal reinforcement for that design method. The internet site fabrication drawings which might be created determined by style and design drawings for reinforcing metal are Rebar Specific drawings. Engineers and Architects make structure drawings to think of the specified strengths based on the rebar detailing that offers diameter, bar shapes, quantities, duration of bars to aid the Website for steering clear of delays and wastage therefore dashing the entire building method.

Each individual rebar is in depth symbolizing a form, duration, and diameter determined by the requirements in the design and style drawing. The Rebar placement will be shown in higher detail which signifies the concrete include, actual site, and Distinctive way of placement if necessary. The rebar information and bar bending schedules might have bar diameter, bar notation, the number of bars, fat in the bars, and period of each bar coupled with mentioning your entire weight to the entire list of bars placed inside the drawing. Throughout the planning of rebar specifics, the inventory lengths of bars are saved in see to ensure there isn't any wastage from your materials.

Rebar Detailing and Reinforcement concrete detailing can be modeled and coded in 3-dimension even though working with 3D Modelling technologies like BIM Modelling Providers. The specialized rebar detailing software program like Rebar CAD and AutoCAD utilized for this goal may well help each member from the structural engineering to organize models, document, observe, and Total control.

Getting comprehended the elemental thought of rebar detailing a bit of structural BIM modeling, let us try and comprehend the want for it in the general design method is. Some in the good reasons are:

Worth of Rebar detailing in Structural BIM Modeling

When 2nd drawings and bending schedules are more likely to be designed and provided, the 3D product may be issued to all or any the workforce associates beginning the consulting engineer and contractor departments because of the steel fixers that may be within the floor level on-web site. The combination of these types of two grow to be Primarily a good choice for web site personnel exactly where web site limitations or congestion of reinforcements continue to be unknown right until you will find reinforcement and fixation on spot. For every single bar, the particular place of correcting is demonstrated throughout the 3D model together with any hindrances or obstructions.

Generating detailing reinforcements in 3D during the 2D procedure is don't just a lot quicker but modeling rebar within a 3-dimensional ecosystem aids take away clashes. Whilst modeling It is possible to visualize if any with the bars tend not to repair within a decided place, thus establish these clashes inside rebar drawings. There is certainly even facility to analyze the reinforcement in full detail as a specific depth illustration just before it truly is currently being requested with the fabricator and complicated cages are assembled off-site.

When There exists a proper rebar detailing solution readily available, a robust and precise reinforcement model is often achieved by importing structural calculations out of your structural Investigation plan. With Automation included modifications in many cases are reflected within 3D rebar detailing Together with needed updates to drawings and schedules quickly when changes are made elsewhere not like getting to execute handbook modifications to 2D sections and views.

As an alternative to dependant on handbook enter from paper schedules, the rebar fabricator can extract facts instantly throughout the design around the machinery. The concrete pours may very well be perfectly-described In the model with other specifics like quantities and volumes to be sure much more precision in handling substance deliveries. This enables higher control and bring about considerably less wastage and lessen in All round fees.

Having 3D in-depth digital designs will not likely restrict the principle profit with a single-phase like this from the engineering and detailing phase but may very well be utilised inside the phases. Obtaining reinforcement totally modeled in 3D, the contractor is confident that it's going to in good shape into locations in the event the trench mesh Sydney time comes it to be fixed on-web-site. The data from the model can be utilized within the subject permitting contractors to carry out a model-centered format through the use of robotic full station equipment and tracking rebar and supplies and identifying where by and when They are going to be demanded.

Fixers present on-web page will probably be In the product setting for that rebar detailing to correctly fully grasp its application, i.e. precisely what is needed location as an alternative to depending on their interpretation of traditional second drawings.

The structural engineers can absolutely and much more promptly produce design and style reports, schedules, and drawings from the 3D model as compared with second models, thus improving style performance. There is much more precision in rate projection based on the rebar quantities produced throughout the 3D design given that they are a lot more reputable in comparison to the 2nd drawing just take-offs. Not just this the portions are entirely traceable, enabling comparisons and checks to obtain done easily.

With these reasons, we can conclude that Rebar Detailing a willpower of Structural BIM Modelling Providers is a person Using the crucial criteria to the General good results through the challenge life cycle. To summarize, having Rebar Detailing the rebar contractor can give attention to generating rebars significant is going to be no have to estimate reinforcement requirements for procurements at your website thanks to successful 3D models. The model will depict the benefits of anchors and laps In the drawings therefore guaranteeing style and design adequacy In combination with lessening wastage. The general waste and time delays are reduced at the website simply because each of the shape drawings are conveniently obtainable. Based on these specifics the bars is often simply fabricated In keeping with the designs and a number of bars expected.

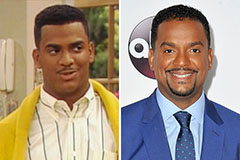

Alfonso Ribeiro Then & Now!

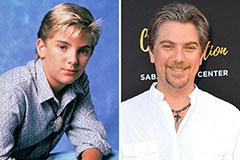

Alfonso Ribeiro Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!